Changing tyres

-

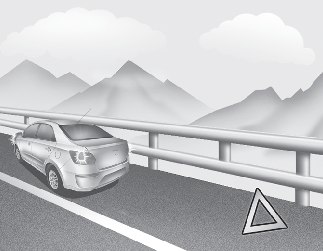

Park on a level surface and apply the parking brake firmly.

-

Shift the shift lever into R (Reverse) with manual transmission or P (Park) with automatic transmission.

-

Activate the hazard warning flasher.

-

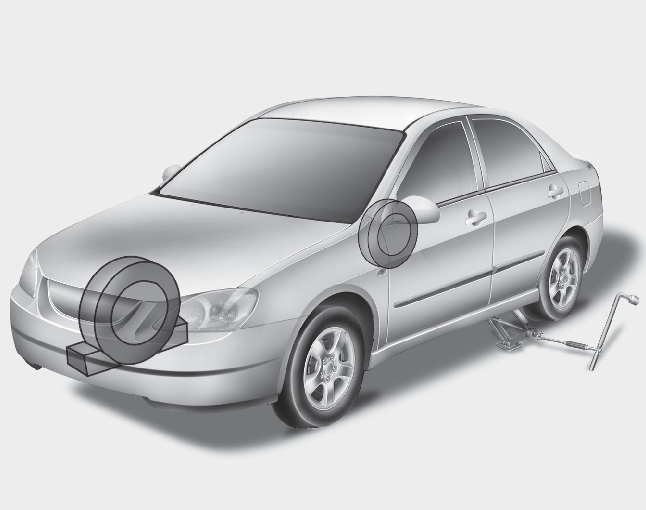

Remove the wheel lug nut wrench, jack, jack handle, and spare tyre from the vehicle.

-

Block both the front and rear of the wheel that is diagonally opposite the jack position.

WARNING

WARNINGChanging a tyre

-

To prevent vehicle movement whilst changing a tyre, always set the parking brake fully, and always block the wheel diagonally opposite the wheel being changed.

-

We recommend that the wheels of the vehicle be blocked, and that no person remain in the vehicle that is being jacked.

-

-

Loosen the wheel lug nuts counterclockwise one turn each, but do not remove any nut until the tyre has been raised off the ground.

-

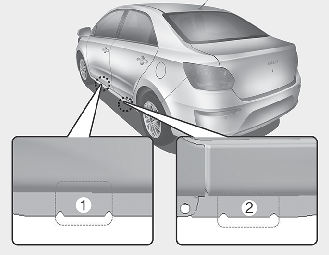

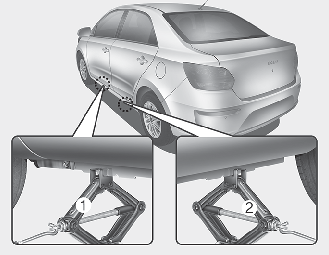

Place the jack at the front (1) or rear (2) jacking position closest to the tyre you are changing. Place the jack at the designated locations under the frame. The jacking positions are plates welded to the frame with two tabs and a raised dot to index with the jack.

WARNING

WARNINGJack location

To reduce the possibility of injury, be sure to use only the jack provided with the vehicle and in the correct jack position; never use any other part of the vehicle for jack support.

-

Insert the jack handle into the jack and turn it clockwise, raising the vehicle until the tyre just clears the ground. This measurement is approximately 30 mm. Before removing the wheel lug nuts, make sure the vehicle is stable and that there is no chance for movement or slippage.

-

Loosen the wheel nuts and remove them with your fingers. Slide the wheel off the studs and lay it flat so it cannot roll away. To put the wheel on the hub, pick up the spare tyre, line up the holes with the studs and slide the wheel onto them.

If this is difficult, tip the wheel slightly and get the top hole in the wheel lined up with the top stud. Then jiggle the wheel back and forth until the wheel can be slid over the other studs.

WARNING

WARNINGWheels may have sharp edges. Handle them carefully to avoid possible severe injury. Before putting the wheel into place, be sure that there is nothing on the hub or wheel (such as mud, tar, gravel, etc.) that interferes with the wheel from fitting solidly against the hub.

If there is, remove it. If there is not good contact on the mounting surface between the wheel and hub, the wheel nuts could come loose and cause the loss of a wheel. Loss of a wheel may result in loss of control of the vehicle. This may cause serious injury or death.

-

To reinstall the wheel, hold it on the studs, put the wheel nuts on the studs and tighten them finger tight.The nuts should be installed with their tapered small diameter ends directed inward. Jiggle the tyre to be sure it is completely seated, then tighten the nuts as much as possible with your fingers again.

-

Lower the car to the ground by turning the wheel nut wrench counterclockwise.

Then position the wrench as shown in the drawing and tighten the wheel nuts. Be sure the socket is seated completely over the nut. Do not stand on the wrench handle or use an extension pipe over the wrench handle. Go around the wheel tightening every other nut until they are all tight.

Then double-check each nut for tightness. After changing wheels, have the system checked by a professional workshop. Kia recommends to visit an authorised Kia dealer/service partner.

Wheel nut tightening torque:

Steel wheel & aluminum alloy wheel:

11~13kgf.m

If you have a tyre gauge, remove the valve cap and check the air pressure. If the pressure is lower than recommended, drive slowly to the nearest service station and inflate to the correct pressure. If it is too high, adjust it until it is correct. Always reinstall the valve cap after checking or adjusting tyre pressure. If the cap is not replaced, air may leak from the tyre. If you lose a valve cap, buy another and install it as soon as possible.

After you have changed wheels, always secure the flat tyre in its place and return the jack and tools to their proper storage locations.

Your vehicle has metric threads on the wheel studs and nuts. Make certain during wheel removal that the same nuts that were removed are reinstalled -or, if replaced, that nuts with metric threads and the same chamfer configuration are used. Installation of a non-metric thread nut on a metric stud or vice-versa will not secure the wheel to the hub properly and will damage the stud so that it must be replaced.

Note that most lug nuts do not have metric threads. Be sure to use extreme care in checking for thread style before installing aftermarket lug nuts or wheels.

If in doubt, consult a professional workshop. Kia recommends to consult an authorised Kia dealer/service partner.

Wheel studs

If the studs are damaged, they may lose their ability to retain the wheel.This could lead to the loss of the wheel and a collision resulting in serious injuries.

To prevent the jack, jack handle, wheel lug nut wrench and spare tyre from rattling whilst the vehicle is in motion, store them properly.

Inadequate spare tyre pressure

Check the inflation pressures as soon as possible after installing the spare tyre. Adjust it to the specified pressure, if necessary. Refer to More Details.

Important - use of compact spare tyre (if equipped)

Your vehicle is equipped with a compact spare tyre. This compact spare tyre takes up less space than a regular-size tyre. This tyre is smaller than a conventional tyre and is designed for temporary use only.

-

You should drive carefully when the compact spare is in use. The compact spare should be replaced by the proper conventional tyre and rim at the first opportunity.

-

The operation of this vehicle is not recommended with more than one compact spare tyre in use at the same time.

The compact spare tyre is for emergency use only. Do not operate your vehicle on this compact spare at speeds over 80 km/h (50 mph). The original tyre should be repaired or replaced as soon as is possible to avoid failure of the spare possibly leading to personal injury or death.

The compact spare should be inflated to 420 kPa (60 psi).

Check the inflation pressure after installing the spare tyre. Adjust it to the specified pressure, as necessary.

When using a compact spare tyre, observe the following precautions:

-

Under no circumstances should you exceed 80 km/h a higher speed could damage the tyre.

-

Ensure that you drive slowly enough for the road conditions to avoid all hazards. Any road hazard, such as a pothole or debris, could seriously damage the compact spare.

-

Any continuous road use of this tyre could result in tyre failure, loss of vehicle control, and possible personal injury.

-

Do not exceed the vehicle’s maximum load rating or the load-carrying capacity shown on the sidewall of the compact spare tyre.

-

Avoid driving over obstacles. The compact spare tyre diameter is smaller than the diameter of a conventional tyre and reduces the ground clearance approximately 25 mm, which could result in damage to the vehicle.

-

Do not take this vehicle through an automatic car wash whilst the compact spare tyre is installed.

-

Do not use tyre chains on the compact spare tyre. Because of the smaller size, a tyre chain will not fit properly. This could damage the vehicle and result in loss of the chain.

-

The compact spare tyre should not be installed on the front axle if the vehicle must be driven in snow or on ice.

-

Do not use the compact spare tyre on any other vehicle because this tyre has been designed especially for your vehicle.

-

The compact spare tyre’s tread life is shorter than a regular tyre. Inspect your compact spare tyre regularly and replace worn compact spare tyres with the same size and design, mounted on the same wheel.

-

The compact spare tyre should not be used on any other wheels, nor should standard tyres, snow tyres, wheel covers or trim rings be used with the compact spare wheel.If such use is attempted, damage to these items or other car components may occur.

-

Do not use more than one temporary spare tyre at a time.

-

Do not tow a trailer whilst the temporary spare tyre is installed.